The sales order scheduler is a service of our software solution Gus³. Its mission is to orchestrate your sales order preparations at best, taking into account your priorities, your human and material resources, and your constraints.

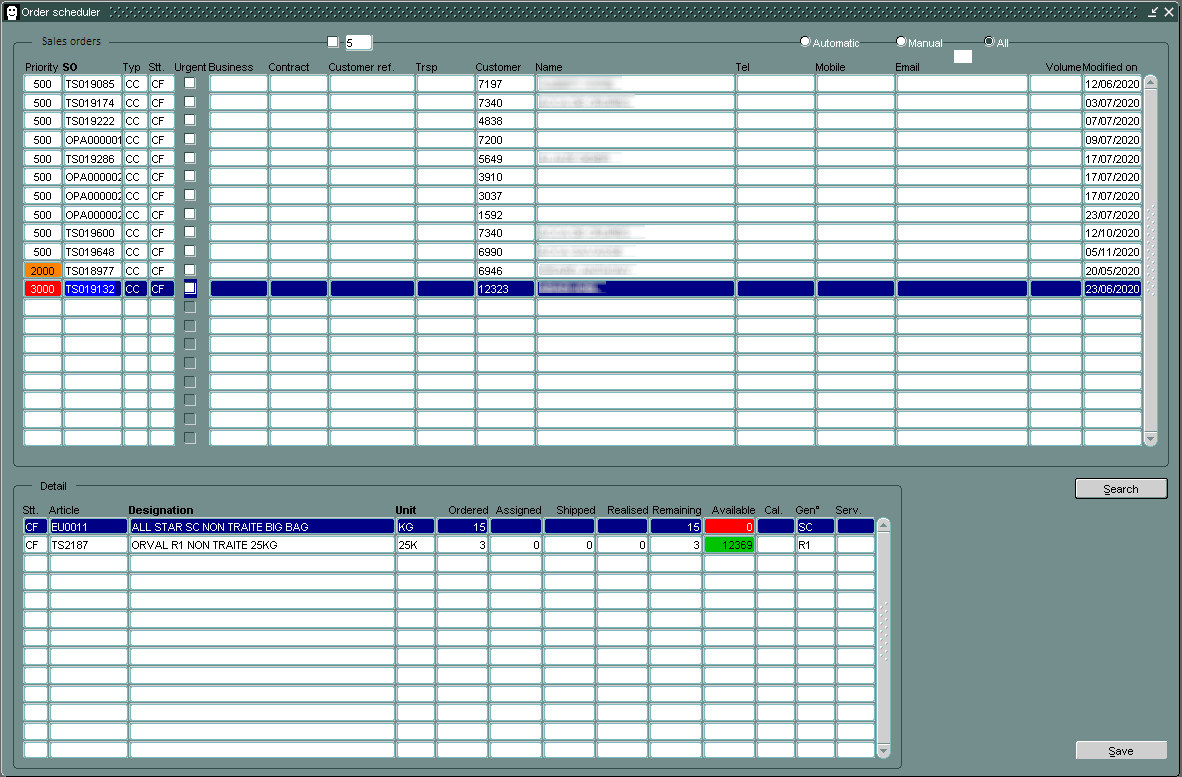

The related screen iGus constitutes a real dashboard for monitoring and controlling deliveries, with very thoroughly designed ergonomics.

- It offers full visibility of the current order book: order lines, details of each order (item references, quantities, volumes, etc.), destination (customer delivered), status of deliveries (orders delivered in full, in part), availability of items still to be delivered, carrier, etc.

- It is updated automatically as the order book changes and the deliveries are performed; users can even set the refresh rate that suits them (eg every 5 minutes);

- Data reading is facilitated and accelerated thanks to the use of a specific color code highlighting the most sensitive information: availability of items still to be delivered, order lines already fulfilled, orders partially deliverable, stock shortage, customer's urgency (season, high season, rush) ...

The order scheduler automatically calculates the optimal order in which your order lines should be prepared, so that your delivery strategy is respected. You can also switch to manual mode, to add personal priorities, on a case-by-case basis, according to your needs.

- Last minute sales orders or changes;

- Out of stock: the scheduler can, for example, offer the picking of 2 sachets of 500 g of a variety if the 1 kg sachet which has been ordered for this same variety is not in stock (provided, however, that this exchange of references is authorized).

The sales order scheduler is able to determine priorities at a very fine level of complexity, from a conjunction of related data:

- Information held by the ERP iGus of our software solution Gus³ :

iGus naturally provides an important part of the information likely to influence your delivery strategy: what you have to deliver, to whom, in what quantity or in what volume, under what deadlines; what you have in stock, at what storage or picking address; what you can deliver (an article reference can for example be in stock without however being available for delivery, because it is reserved for another process); what you can manufacture; what you need to purchase ... - The priorities that define your delivery strategy and that we integrate into the tool, by simple configuration:

While the sales order scheduler includes settings as standard, the latter can nevertheless be customized at will. In fact, we have designed the scheduler so that it has the capacity to integrate a very large number of parameters. The setup times obviously depend on the complexity of your organization and your rules. But once the scheduler has been carefully configured, the resulting gains can turn out to be exponential. And if your priorities change, you don't have to worry about cumbersome and costly software updates: just change the settings.

The sales order scheduler relies on all this data to optimally meet your delivery requirements:

- Which order lines to favor at all costs?

By default, the scheduler is configured to limit backlogs by favoring, among the most urgent orders, those which can be delivered in full. But you can make any exceptions you want. So, for example, you can decide to deliver certain orders drop by drop, as and when their item references become available, even if this generates backlogs, because your customer is a priority or in absolute urgency. - What order lines should be prepared to optimize the number of order preparations by the carrier's lift time?

The carrier lift time is a primordial criterion for the scheduler, which may have the task of squeezing as many order lines as possible within the time allotted for their preparation. To do so, the scheduler relies on objective, verifiable and quantifiable criteria, such as the forecast preparation times per sales order, etc. These are calculated from the weight of the items handled, their quantity, or even other more specific criteria such as the way they are managed. Indeed, a batch-managed item often requires more handling than an item that is not batch-managed, such as for example the reading of a barcode each time a sachet is taken ... - What degree of urgency, for what type of order?

The nature of the order can have a significant impact on the imminence of its preparation. So, for example, you could decide that orders placed over the counter or on the Internet should always be given priority. - What degree of urgency, for what type of client?

Plant growers subject to imperative sowing requirements, marketplaces requiring delivery within 2 days maximum, cooperative members' periodic and regular orders ... The sales order scheduler manages the degree of urgency that you assign to your customers, whatever the urgency: absolute, contextual, seasonal... - Which personnel to assign to which order preparations?

Preparing certain orders may require special skills or knowledge. The scheduler is able to offer you an optimal match between the profile of the order pickers and the tasks inherent in certain order preparations (assembly, machining, handling of sensitive / toxic items, batch-managed products, etc.). - Which material resources to allocate to which orders?

By material resources, we can understand the tools necessary for the preparation of certain orders (cutting, etc.), the most suitable places for preparation (warehouse, workshop, depot, etc.), the equipment used for collecting item references (forklifts , preparation trolleys, etc.) ... Thus, the scheduler can fully take into account the need to avoid any risk of contact between qualitatively incompatible products (food / toxic products). And you can also make sure that your order pickers won't have to go looking for the tools they need at the other end of the workshop! - Which routes should be favored to collect a maximum of items in a minimum of steps, or to limit traffic jams in the storage aisles?

If your order pickers take fewer steps, order picking takes less time, and you deliver more. The reduction in preparation costs is sometimes very substantial: we have gotten up to 2,7 times more efficiency. For this, the scheduler can group the order preparations by geographic proximity of the storage aisles or picking addresses. And the savings achieved become exponential when the order scheduler is coupled to the Salvo mode, so that the order pickers can pick several different orders simultaneously. - Etc

Any settings are possible, but each setting is unique and reflects a very specific delivery strategy: yours!

And to go on putting the odds in favor of the quality and efficiency of your deliveries, myGus, the procedural component of our software solution Gus³, can take over in the storage aisles. Objective: to secure the preparation of orders, from picking to packaging. Indeed, it is the last step before the departure of the goods to the customer's. Even the slightest misstep can have detrimental consequences, whether it is delivery error or stock discrepancy.

To avoid such inconveniences and their often unfortunate consequences, myGus, coupled with a barcode reader, provides precise and systematic control of each item reference taken (quality, quantity), in real time, much more efficiently than a simple weighing. So with myGus, you are assured to fill your packages with the references that have been ordered, in strict compliance with the quantities that have been specified on the order lines.

For more information on the order scheduler, do not hesitate to consult our team.