Initial reception

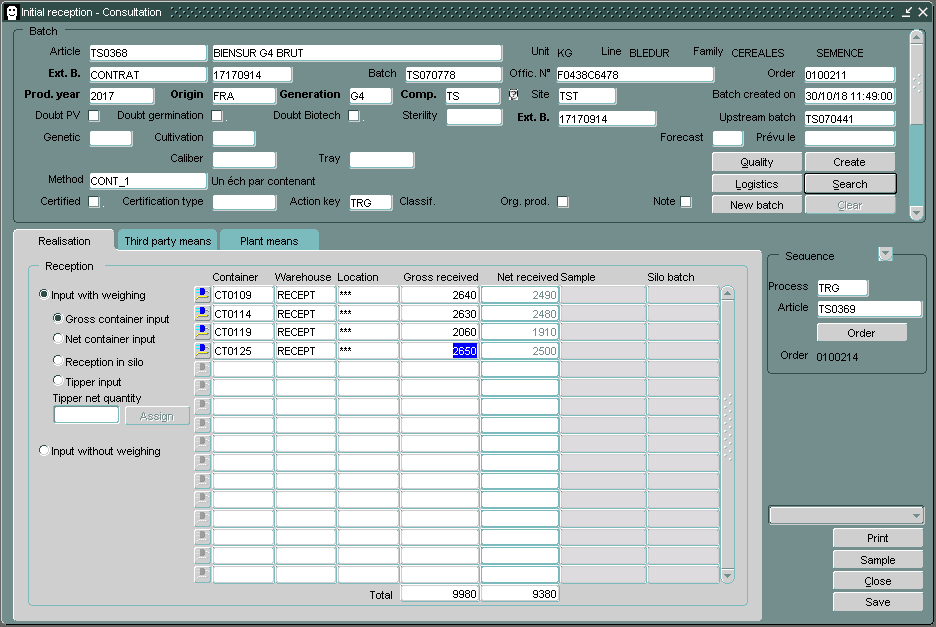

In the Initial Reception screen, you enter the batches and stocks that enter the seed station, regardless of the seed stage. Reference information, such as the production contract, is the link with the phases located upstream of the seed station. The screen configuration automatically adjusts to the context. Batches and stocks can be received without any container, or in containers, or even in silos. They can also be distributed from a tipper. Stocks are assigned to warehouses and storage locations.

The external batch number is the link with an external system: production, subcontractor purchases or supplier purchases, free supply. The certified batch number (once the batch has been validated by the official seed control and certification agencies) is stored. Stocks of treatment products can also be entered by means of initial reception.

The initial reception can be linked to an input management.

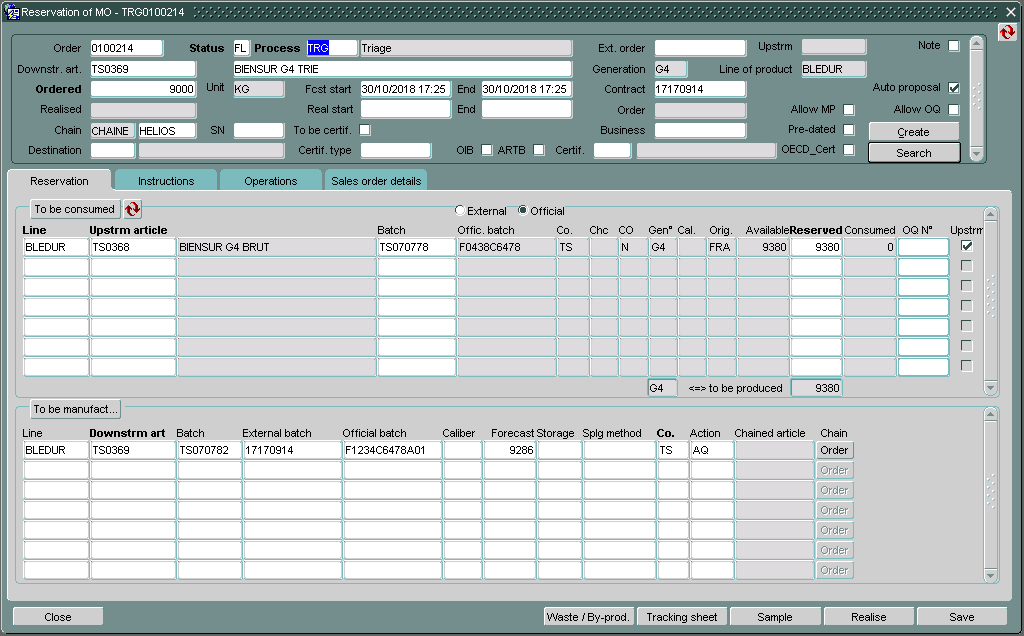

Manufacturing orders

Using a single mechanism, it is possible to manage all manufacturing orders in a simple and user-friendly way:

- A reservation screen,

- A realization screen.

IGus manages the classic manufacturing processes:

- Calibration or sorting, re-calibration and density table: iGus records, per batch, the calibration plan as well as the realization of the order; waste and by-products (eg: force-feeding / birding) are recorded. It is possible to recycle certain batches which have an intermediate quality and will be sorted again.

- Conditioning (bagging / re-bagging / re-labeling): the seeds available as well as the consumables (treatment, bags) are reserved. With iGus, packaging can be ordered according to the quality of the seeds.

IGus also adapts to other manufacturing processes: assembly, batch splitting, silo racking, packaging, etc. In fact, more than 60 processes have already been pre-configured, and you can create more! And for each process, iGus also manages waste from manufacturing. It is possible to configure the mechanism of manufacturing orders.

Tracking sheets provide the link with the seed station.

IGus adapts to different factory circuits. Originally, iGus was designed for corn with intermediate storage. IGus was then adapted to faster or different circuits: sequencing calibration / bagging (treadmill), batch for recycling (seeds to be sorted again).

The quantities realized can be entered in raw or net quantities, as you prefer. IGus calculates the net quantities.

In iGus, you can sample and number your receptions for each manufacturing operation.