With the secure web service tiGus, use the data you want, how you want, when you want, where you want, and exchange it with whoever you want, in complete confidentiality

10 years ago, SemWare designed the Web application tiGus, a secured data sharing tool. This application has come to complete the already existing software offer: iGus, a powerful ERP solution, and its procedural companion myGus, an expert in secured data acquisition in the field.

TiGus aims to facilitate the communication of operational data, in real time, while guaranteeing the absolute confidentiality of the data communicated:

- internally, between employees belonging to the same company (production management, inventory management, sales management, etc.),

- externally, between partner companies (clients, suppliers, subcontractors ...).

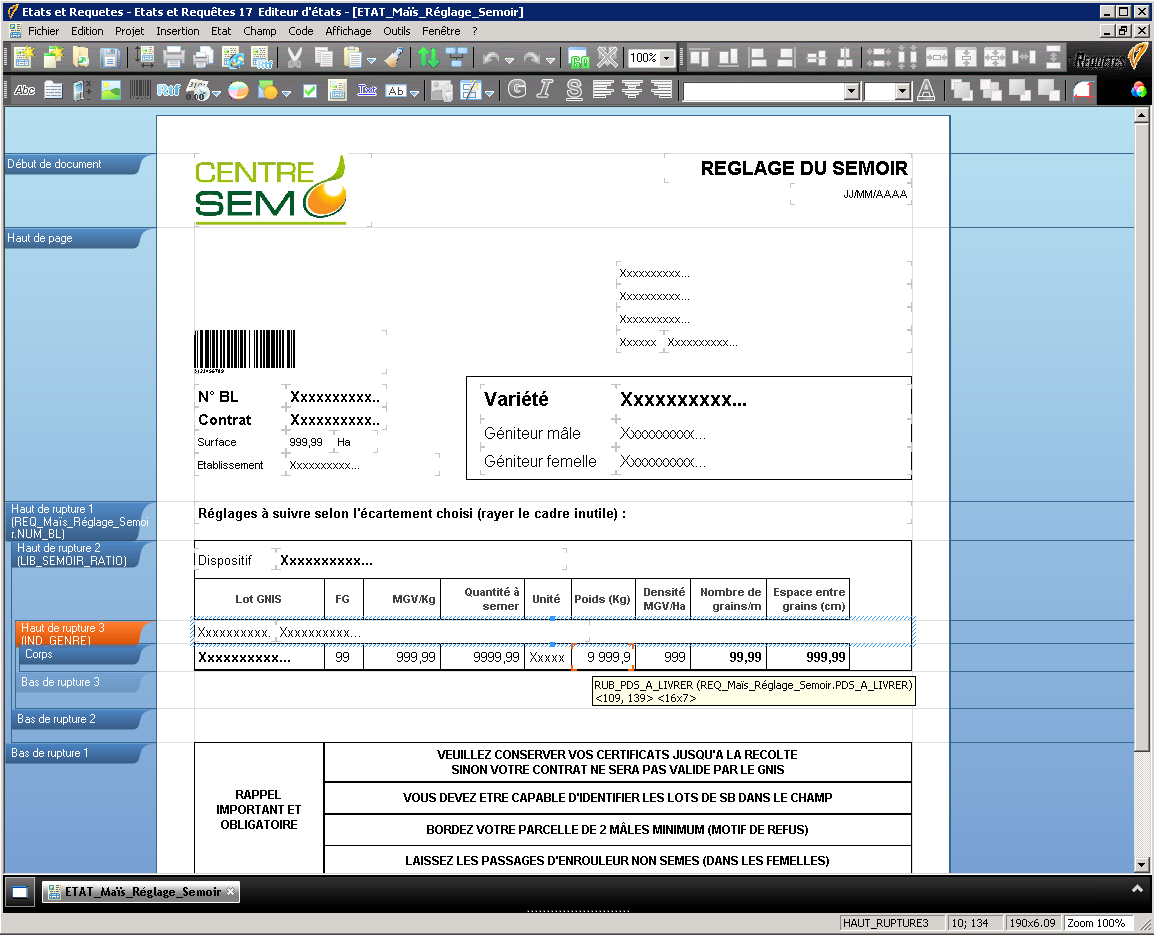

TiGus is a flexible and easy to use tool. And you are autonomous: unlike other existing tools, with tiGus, you don't need any computer engineer to convert the database structure or develop reports and modify them as needs change.

With tiGus, users are at the center of the communication system. They are the real recipients of information. And this is precisely where the originality of SemWare's approach lies! With tiGus, users do not have to wonder where the data come from. They do not need to have special computer skills or knowledge. In fact, users only need a web browser and a tiGus account to access the essential data. And they can view them as easily as if they used a spreadsheet tool.

A wide range of ready-to-use dashboards, covering most of your activity

10 years after its creation, the tiGus Web application totals about XNUMX standard dashboards providing complementary synthetic views on all the data entered or generated in your ERP, as your processes unfold.

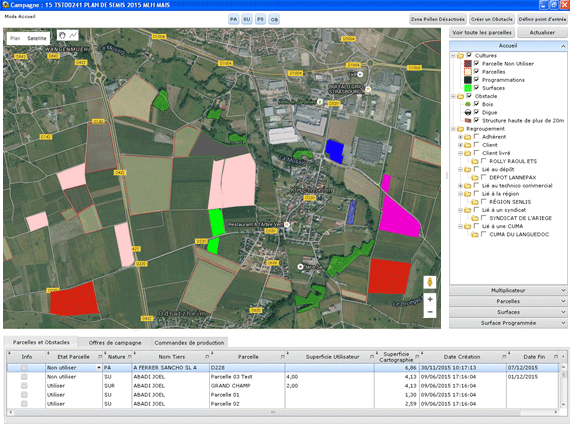

These standard dashboards were designed mainly for players in the seed industry: contract givers, agricultural cooperatives, seed stations. Their objective is to respond quickly to most of the questions that frequently arise during the processing of seeds, from the initial reception of the harvests to the delivery of the bags containing the finished products:

- What quantities have been put into stock for each seed production contract?

- What quantities, in tonnes, have been ordered, produced? What quantities still have to be manufactured, bought? What quantities have been carried over? Per customer and item, per item, per product?

- What quantities have been consumed and received, per order and type of movement? What is the corresponding loss rate, in kilograms and in percentage?

- What is the total quantity in stock, all subcontractors considered?

- What is the quantity in stock, in number of grains?

- What was the status of the stocks on this or that (prior) date?

- What are the latest analysis results for the stock in this or that container?

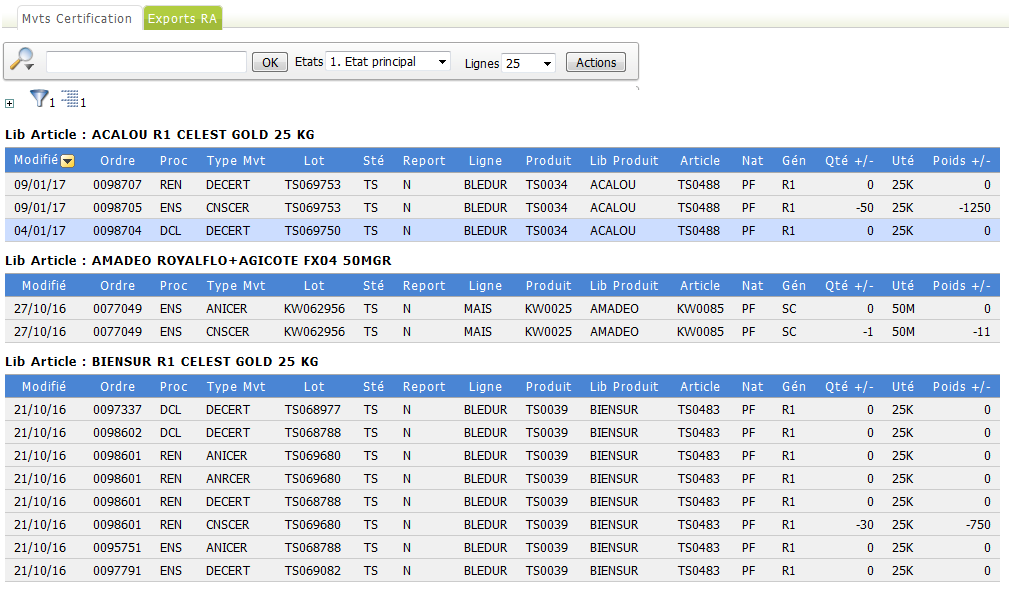

- What certification movements have been made, per batch?

- What quantities are available for delivery regarding each article?

- What shipments have been made on behalf of this or that carrier?

- What are the expected service invoices?

- Etc

And if the dashboards currently present in tiGus do not answer all the questions you have, then the SemWare team will develop specific dashboards, tailored to your needs, for your exclusive use! Therefore tiGus has proven its effectiveness in other fields of activity than seed, such as the rail industry.

Confidential and secure access to targeted and up-to-date data

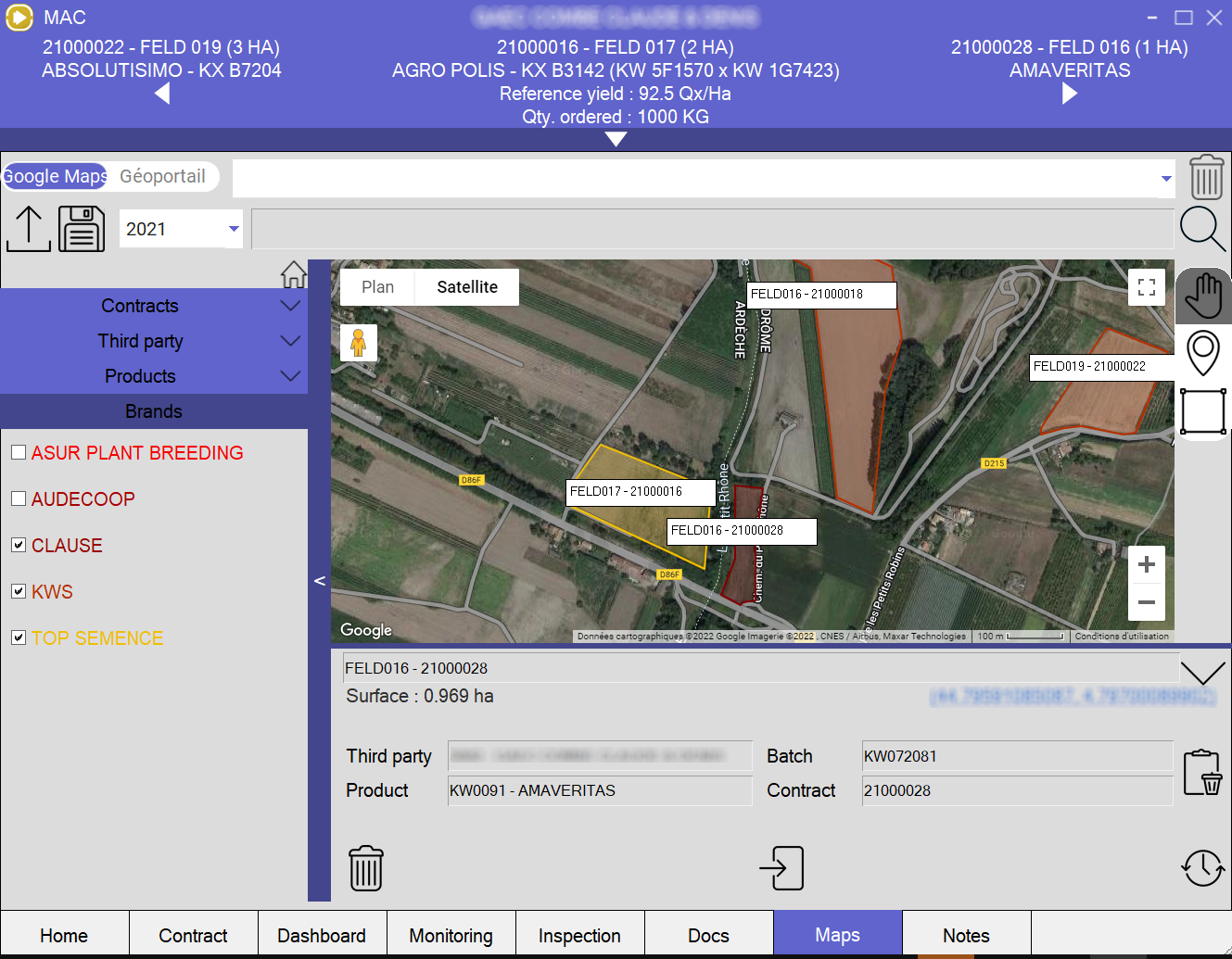

Each user only has access to the data that concerns his function or his mission in the company. The settings of access rights are done for each user profile and for each dashboard. The access to the data is confidential, and you go straight to the main point.

To access his data, each user has his own private space. He can connect when he wants, wherever he is, with the means he has (PC, tablet, smartphone). Thus, data security and flexibility of use go hand in hand, for your comfort.

The data present in the tiGus dashboards tiGus are the same as those entered or generated in the management software. If the ERP data change, the data present in the tiGus are updated automatically. The update frequency can be configured, depending in particular on the user's software configuration. When the database allows it, tiGus favor real time.

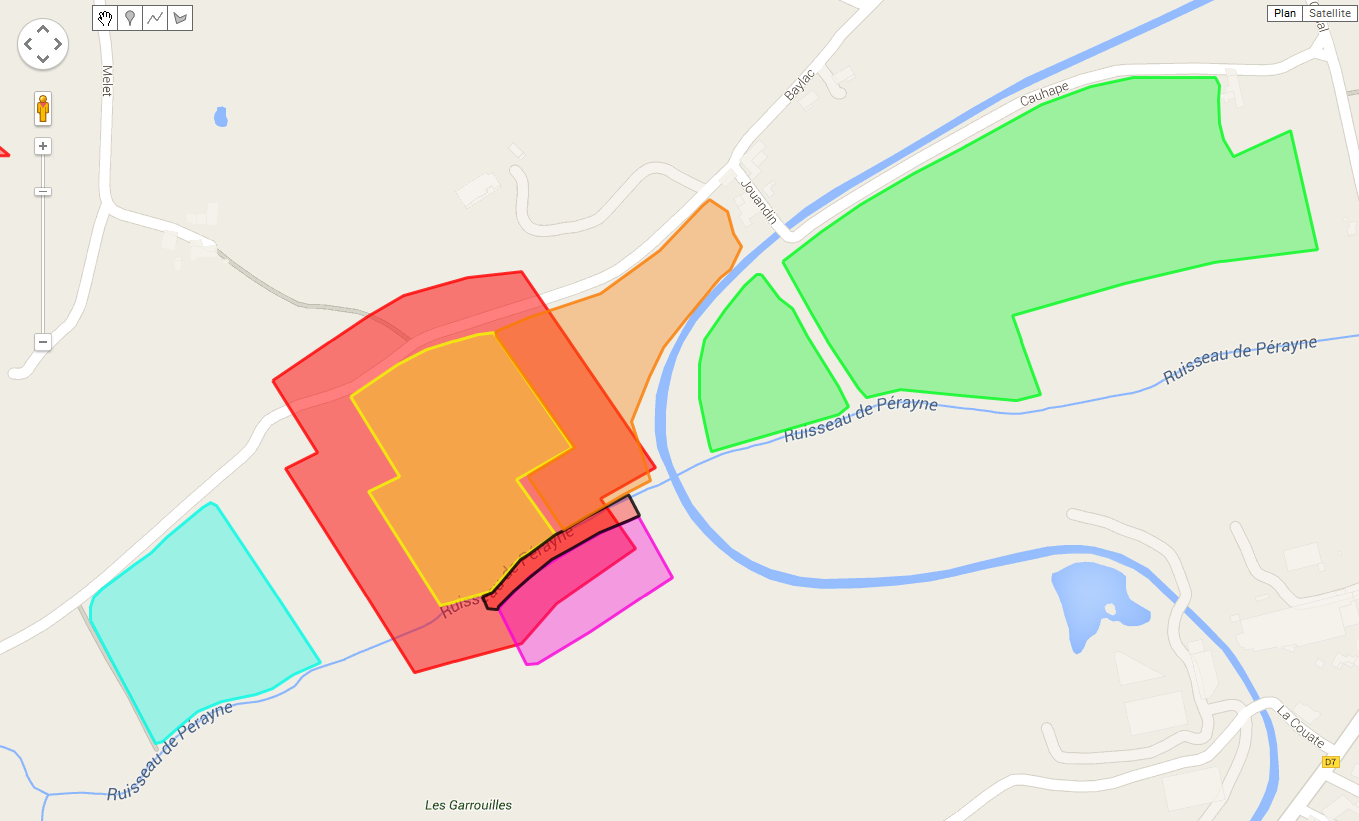

A powerful and customizable data analysis tool

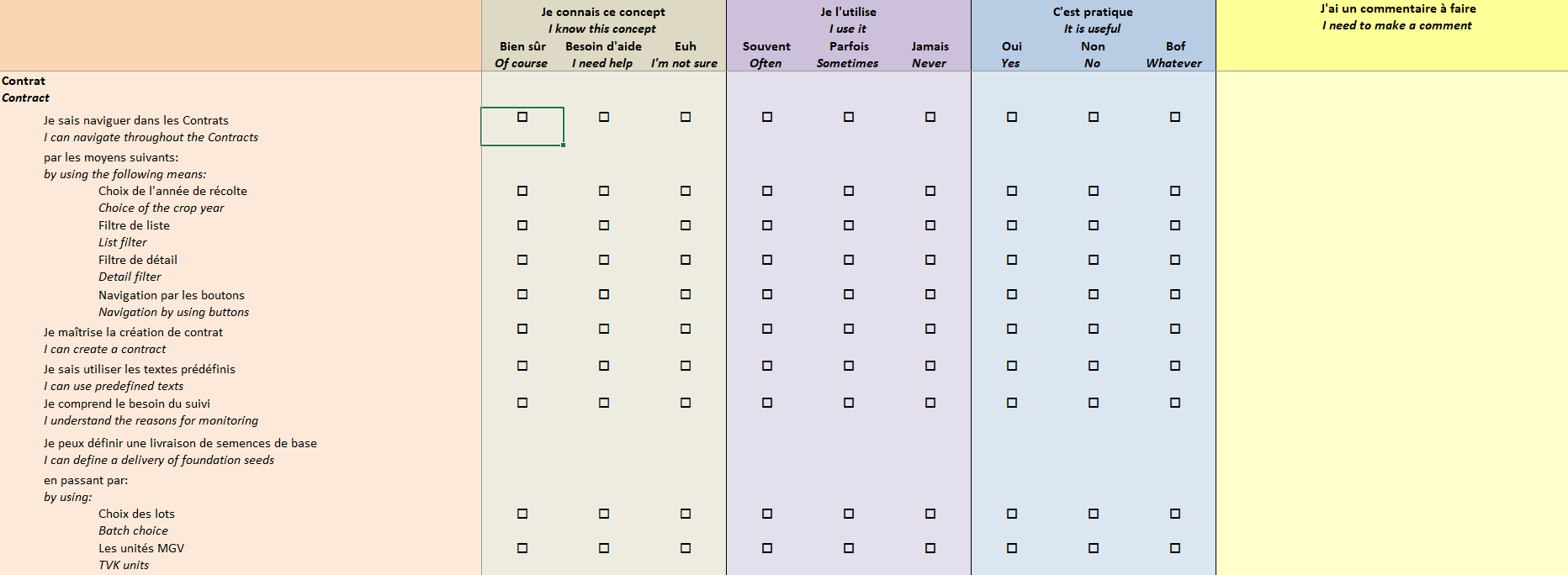

Users can manipulate their data at will, customize their standard dashboards as easily as if they were using a spreadsheet, without the need for special software.

To do all this, they are provided with powerful functions such as filters, control breakdowns, highlighting of lines and cells, calculations and functions (total, average, number of records, number of distinct values, minimum, maximum, median ), aggregations ...

It is also possible to create all kinds of graphics ... And it is easy to switch from the dashboard to the corresponding graph.

Some dashboards even have dynamic navigation, which automatically reduces the number of columns displayed to the number the user strictly needs. It is very practical when the data are numerous (qualitative characteristics ...).

If they wish, users can keep their personalized dashboards in their private space. To do this, they just have to save them. And they can also download them in Excel format or print them in pdf format.

Fully automated data exchange

A contract giver needs to know in real time the status of all his stocks, including those whose propagation is carried out by subcontractors (agricultural cooperatives ...). As for these subcontractors, they need to receive continuous orders from the contract giver.

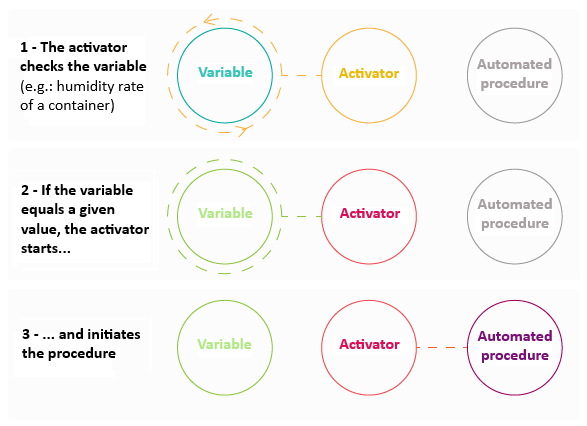

The tiGus application has been designed to respond to this type of situation, by making communication autonomous between partner organizations (clients, suppliers, subcontractors ...).

These data exchanges are carefully configured in the management software: what data will be shared, with whom, according to what frequency, according to which confidentiality criteria ... Thus, the data transfers will be done in a fully automated way, only to the private spaces of the people concerned.

As for the senders, they can at any time check if the data they wish to transfer have been transmitted. For this, all they have to do is connect to their own tigus account.

And this is how :

- a contract giver can have visibility on all the stocks, all subcontractors considered, using a single tiGus, updated in real time,

- a subcontractor can automatically receive his delivery orders, or other standard files, directly in his management software, without having to re-enter them.

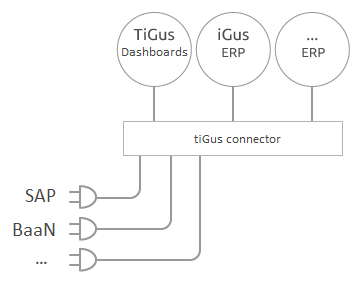

An application to be consumed without moderation, and without any restriction related to the nature of the management software used

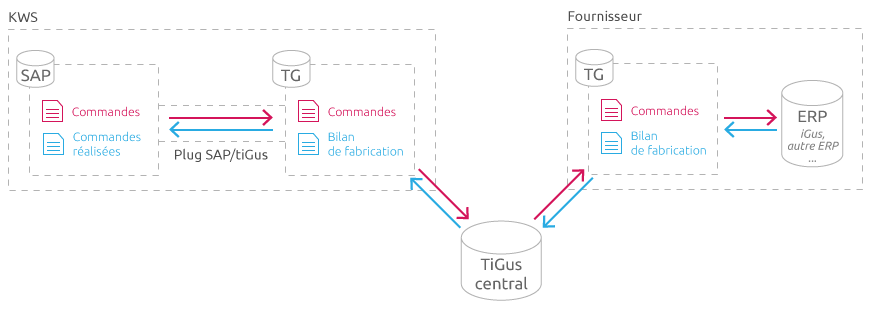

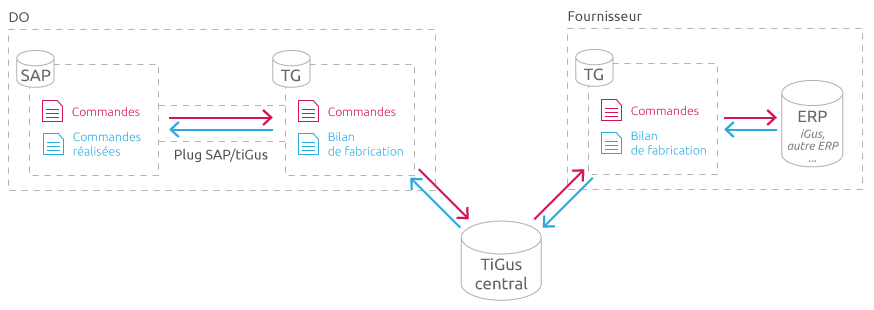

The tiGus application has EDI interfaces, as standard. Thus, with a single application, you can exchange data with whoever you want, even if the management systems are different: the tiGus application plays the role of interface, ensures the compatibility of the exchanges and guarantees the integrity of the exchanged data.

In 10 years, tiGus has successfully orchestrated numerous exchanges of information between various management software, in different contexts.

Thus, a contract giver equipped with SAP can subcontract part of its production and manufacturing to different seed stations equipped with the ERP iGus... Thanks to tiGus, this contract giver can send their manufacturing orders to all their subcontractors, in a fully automated way. In this case, the data present in the orders (varieties, quantities, etc.) are transferred directly from SAP to the ERP iGus, via the tiGus application which plays its role of interface between different ERP. The manufacturing order coming from SAP automatically generates a manufacturing order in the ERP iGus... And there you go!

TiGus has also proven its worth with the BaaN ERP. ERPs of this type manage physical flows. They collect a multitude of data but they do not make it possible to do the reporting or to have an overview on the data stored. Leveraging their long experience of the BaaN software, SemWare have therefore developed a tiGus / BaaN interface to easily consult the data present in the BaaNERP, in the form of ready-to-use dashboards. In 10 years, several dashboards have been created:

- Business, to estimate the overall cost of a project, from all the elements that constitute it,

- Finance, to group together all the accounting entries,

- Justification of 408, to detail the account of accrued invoices,

- Time tracking, to summarize, per operation, per operator, per week and per day, the manufacturing times and manufacturing costs, realized and forecast.

A small investment for a large service

There are very powerful tools on the market to help users access their data without needing to know the structure of the database. Business Object is one of them. This rich environment provides reports and dashboards that evolve continuously. However, its license is very expensive and very often only very large organizations can afford it.

With tiGus, we offer a solution accessible to all types of organizations, including the smallest. It is therefore very affordable financially.

In addition, the more tiGus reports, the more money tiGus makes you: this application helps you access your essential data, to make the right decisions, at the right time! Thus, you get a real return on investment very quickly, on the one hand concerning the application tiGus, on the other hand concerning your management system and the mountain of data that lie dormant in it ... Decidedly, with tiGus, reporting is real fun!

And if YOUR performances were counted by tiGus ? Do not postpone: consult our business experts without further delay, to study with them the solutions that will suit you ...

Also read the news:

{autotoc enabled = no}

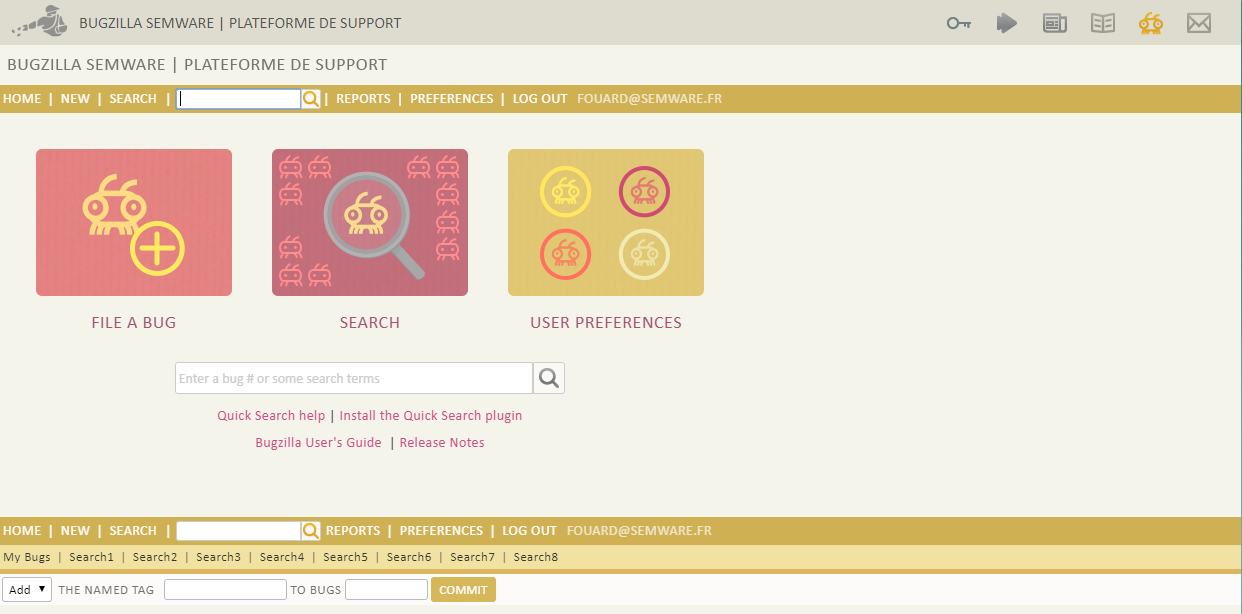

... to go to or return to the home page.

... to go to or return to the home page. … To connect and access secure information.

… To connect and access secure information. ... to reach the

... to reach the  ... to reach the

... to reach the  ... to access the

... to access the  … to

… to