A stock is linked to an article, a batch, a place (site, warehouse and location) and a container.

The management of physical stocks is complemented by the quality aspect: a stock can be available only if it complies with the quality rules.

There are 2 types of stock orders:

- movements, during which the material does not change container, but the container changes location (example: TRI = Internal Transfer);

- transfers, during which the material changes container (example: TRV = Transfer).

Other Stock Order (OS) type processes exist. For example :

- LIV: delivery,

- MEC: containerization,

- REL: return after delivery,

- TAS: piling,

- TRE: delivery external transfer,

- TRF: reception external transfer.

Carrying out these processes causes a stock movement of the batch.

Storage in silo is a special case of transfer.

In addition, you can reserve batch or item quantities per production order. Thus, a stock is always qualified by a status: in control, reserved or available. This mechanism governs the scheduling and planning of manufacturing.

Stock movements trace the history of stock down to the finest level: traceability is total. Changes in quality and ownership are also translated into movements, which makes pre-invoicing possible.

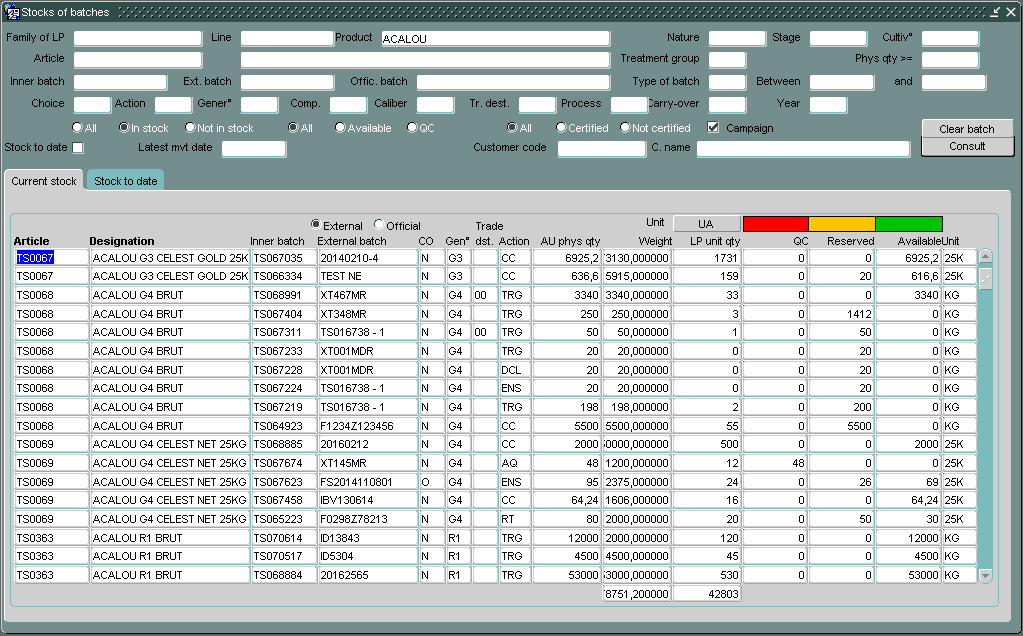

Stocks are kept up to date at all times, whether they are seeds or consumables. You can view the data on a screen. You can also use reports to view inventory per location, product line, product, warehouse, company, seed stage, globally or in detail. In fact, you can use all the characteristics of the products, articles, batches, sites ...

You can manage stock operations such as moving, transfilling, containerizing, or piling.

At the end of a campaign, the remaining batches are marked as “carried over” batches. Thus stocks are carried over when a new campaign starts.

A historical base shows the evolution of batches, movements ... throughout the past years.

With "Business Reservation" you can reserve a quantity of batches for a market before any manufacturing has started.

The property

The batch carries ownership. Ownership movements are traced: purchases/sales, whether explicit or implicit (triggered by a production order, such as bagging). Thanks to these elements, pre-invoicing and stock accounting are possible.

IGus can calculate a default company from characteristics (example: product line, generation ...).

Service orders

IGus records manufacturing orders and / or delivery orders. Production orders, when they exist, drive the creation and monitoring of production orders. The seed station manager can adjust the manufacturing schedule, relying on reports that compare the quantity ordered and the quantity realized. His task is facilitated by a tool which helps him select the batches.

Deliveries

IGus manages deliveries with or without service orders. Only available batches can be delivered.

The preparation note informs the forklift driver of the reserved goods. When the loading is finished, the operator edits a delivery note.

Returns can be entered on a specific screen.

Inventory

In iGus, each stock movement is recorded, from one end of the process to the other, whatever the nature of the stock concerned (raw, semi-finished, finished products, consumables, etc.). Thus, at any time of the accounting year, you are aware of your stocks in quantity and quality.

The physical inventory, whether annual or continuous, starts and ends in iGus, on the date that suits you. The inventory-related features are grouped into one screen. And there is a specific tab for each inventory step.

First you reserve the stocks you want to inventory. This is the subject of the first tab. These stocks will remain blocked until your inventory has been validated. You can select your stocks by store, by location and by container. Thanks to this very fine level of selection, you can isolate small targeted parts of your stocks. Thus, you can, without hesitation, start inventories on the fly: only the stock that concerns you will be blocked.

In the second tab, you compare the initial, or theoretical, quantities to the quantities obtained by physical counting. These can be entered manually. They can also be recorded there automatically if, in the field, you use our myGus procedural tool. The stock differences are automatically indicated in orange. And when they have been checked, and/or corrected, iGus automatically displays them in green.

Then comes the time for verifications and justifications. This is the subject of the third tab: it will help you investigate your stocks. This is why this tab displays the history of all movements, in detail: movements of material consumption, inventory movements ... You will find all the information you need concerning the stocks you want to justify. So you will quickly and easily identify why you have less stock here, or too much stock there. And you will be able to justify all the discrepancies, immediately.